Animated Diagrams with TSV B

During burning steam is released from the fuel, among others. If the flue gas is hot enough, the steam exits through the chimney together with the flue gas. However, if the flue gas gets cooler at some spot, steam condensation occurs. The condensate may contain very aggressive substances that cause fast corrosion and deposit formation on heat transfer surfaces (tarring).

This can be prevented by using TSV load valves that mix cool return water from a heating system or thermal store with hot water from the boiler flow. This way the whole boiler heat exchanger is kept warmer, at temperatures that will not allow condensation to occur, which makes their service life significantly longer and the boiler efficiency higher.

The influence of load valves on boiler operation is obvious from the animated diagrams.

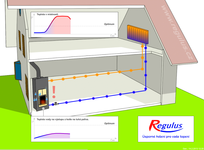

Boiler operation without a load valve

A simple system of heating with a fireplace insert/boiler with no load valve. In this system, vapour condensation may occur. Due to cold water returning to the boiler, aggressive condensate forms on its heat transfer surfaces. The condensate contains products of combustion that can be very aggressive, especially when wood or solid fuels are burned, and may cause tarring – fouling of boiler heat transfer surfaces and corrosion. Fouled heat transfer surfaces cause deterioration of the boiler efficiency, leading to its destruction from corrosion.

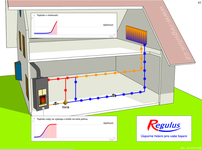

Boiler operation with a TSV B load valve

A system of heating with a fireplace insert/boiler with a load valve. TSV load valves blend cold water returning from a heating circuit with hot water from a boiler. This way the whole boiler heat exchanger is kept warmer, at temperatures that do not allow condensation to occur which brings significantly longer service life and higher efficiency of the boiler.

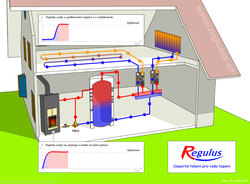

Boiler operation with a TSV B load valve and thermal store

A system of heating utilizing a TSV B load valve and a thermal store. A thermal store is heated up by heating water while storing heat and releasing it into the heating circuit just in the amount needed to heat the building. The building is not overheated, and suitable sizing of the thermal store together with a smart controller may bring almost the same heating comfort as if a switched source was used (gas-, oil- or electric boilers etc.). In such a case the source works within its nominal parameters, i.e. with the highest possible efficiency which always brings not only high savings in heating costs but also a substantial service life extension of the boiler.